Tech Entrepreneur Stefan Larsson, founder of companies like LaserCAD, Procedural Labs and BIMobject today announced his new tech startup, lostboyslab a procedural driven design studio with 3D print farm and with cloud platforms surrounding and integrating the CAD system Autodesk Fusion 360.

The lostboyslab, will have sustainability in focus and be a protector of our environment. It will enable designs to support additive manufacturing (3D printing) with mainly recycled, biodegradable and recyclable materials with traceability through smart products and IoT. lostboyslab will build software platforms, machines and know-how for every step in the process that will be scaled all over the world.

The mission for lostboyslab is to build demand for recycled plastic locally and provide a digital supply chain platform globally, as well as solutions that will allow for mass customisation and IoT traceability with NFC chips integrated in the products. The objective is to build a scalable lab solution that can be franchised and replicated all over the world.

The 3D print farms will be run by solar power and transports will be using electric vehicles charged from renewable sources. Lostboyslab will be a mix of design, IP, processes, machines, cloud platforms that will enable a circular approach to manufacturing of components and products in multiple industries.

Today lostboyslab opened the first lab in the South Coast of Sweden, also called Alpha Zero. This is where new products are designed and 3D printers, material, processes are researched, tested in production, as well as special machines for other tasks like shredders, lasers and extruders.

Multiple software development projects are running at the Alpha Zero lab, to enable a truly digital supply chain that will open up for central parametric designs to be accessed in local 3D print farms to be manufactured. This alone will save transportation cost, no more middlemen like supply chains and distribution companies, cutting inbetween and the product can be tailored and customized for the buyer in that particular place and time. The digital representation of products and solutions changes everything, products can be made in new materials, instantly, personalized and manufactured locally with locally collected plastics.

Lostboyslab focus will be on sustainability and enable a lifecycle approach to components and parts in multiple industries.

We are dedicated to fight the enormous plastic waste and pollution of our oceans, beaches and land. We will build demand for trash and reuse it instead of using toxic and virgin materials. Every lab will be part of a common platform where knowledge, parametric digital products, process and know-how will support a more sustainable and environmentally friendly world. A world where we think all the way through, a circular mindset including the consequences of production, use of the right materials and with the power of cloud technology adding information, traceability and responsibility to the physical product.

We are no ordinary design firm, engineering company or factory. We are different and we dare to be. We will not settle with an easy way forward, we want to find the best solution, the future of our kids depends on it. We work with a community of creators, makers, modelers, designers, art directors and even business angels.

Welcome to the lostboyslab

For more info please email: info@lostboyslab.com

Web site: https://lostboyslab.com

Lostboyslab AB

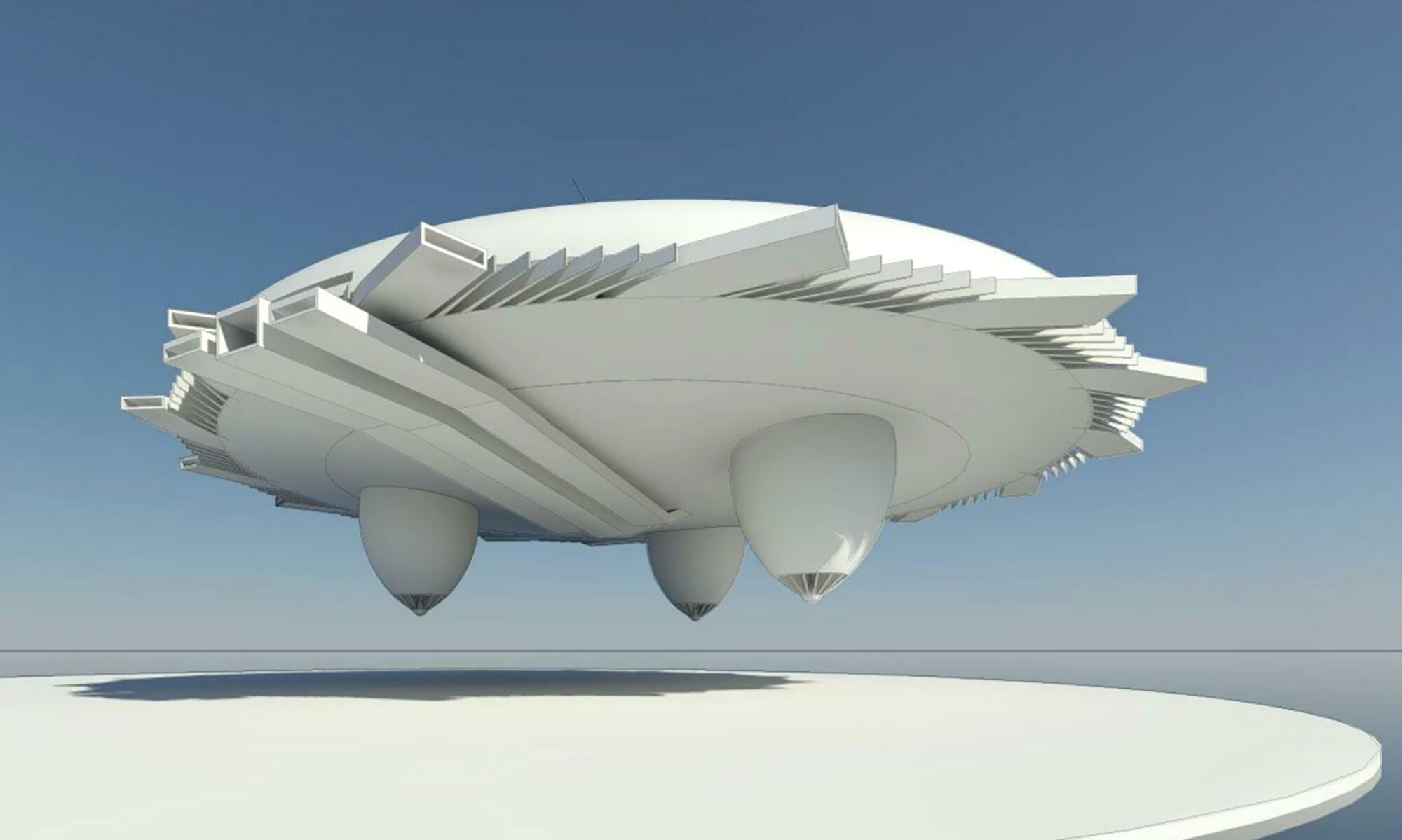

The design studio revolves around disruption and imagineering, constantly pushing the limits of technology both in fabrication and materials. We are on a mission to find new ways using new fabrication opportunities and new materials, that in combination with outside of the box thinking, finding the best process with software, platforms, 3D modeling and printing technology. We are different, we don’t like ordinary or almost great, we want to create and design products that break boundaries and have a functional approach, but at the same time are developed to be manufactured in the fastest and smartest way. It’s a brave new world where parametric design, artificial intelligence, generative design and millions of simulations will hit your digital designs and are totally optimized for additive manufacturing.